Nickel Alloy TIG Rods

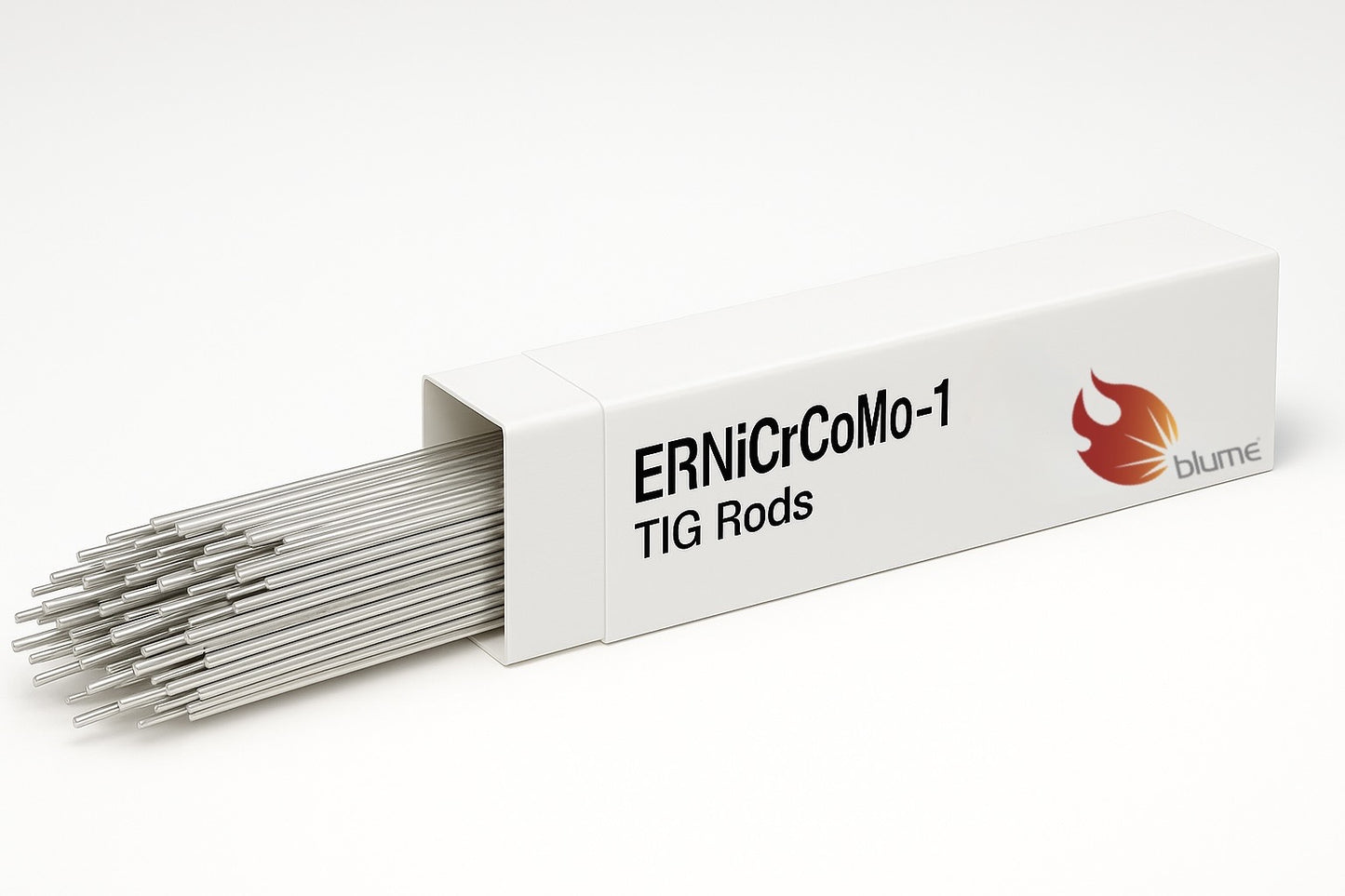

BLUME® ERNiCrCoMo-1 (TIG)

BLUME® ERNiCrCoMo-1 (TIG)

Specification: ASME SFA/AWS A5.14 ERNiCrCoMo-1

Ultimate TIG Rods for Extreme Alloy Applications

Engineered for exceptional corrosion resistance, high-temperature strength, and superior weld performance, BLUME® ERNiCrCoMo-1 TIG Rods are ideal for nickel-chromium-cobalt-molybdenum alloy welding in the most demanding industrial environments. Delivering smooth arcs, clean welds, and reliable mechanical integrity, these rods are a professional’s first choice for critical, high-performance projects.

Perfect for chemical, petrochemical, marine, and power generation industries, BLUME® ERNiCrCoMo-1 TIG Rods ensure precision and durability in every weld.

BLUME® ERNiCrCoMo-1 vs Standard ERNiCrCoMo-1

Key Features

Key Features

✅ Premium Ni-Cr-Co-Mo Alloy – Maximum corrosion and heat resistance

✅ Smooth, Stable Arc – Ensures clean and precise TIG welds

✅ High-Temperature Strength – Maintains mechanical integrity under extreme heat

✅ Exceptional Toughness & Ductility – Minimizes cracking and deformation

✅ Strict Quality Control – Consistent performance across all batches

Recommended Application

Recommended Application

✔ High-temperature and high-pressure piping

✔ Chemical and petrochemical processing equipment

✔ Offshore oil & gas components

✔ Power generation plants (boilers, heat exchangers)

✔ Marine and aerospace applications

✔ Fabrication requiring maximum corrosion and heat resistance

Product Data Sheet

Product Data Sheet

FAQ

FAQ

Q: Why choose BLUME® ERNiCrCoMo-1 TIG Rods?

A: They provide premium corrosion resistance, high-temperature strength, and precise weld quality for critical alloy applications.

Q: What shielding gas is recommended?

A: 100% Argon ensures optimal TIG welding performance.

Q: Can they be used in marine or offshore environments?

A: Yes. Their Ni-Cr-Co-Mo composition provides long-lasting corrosion protection.

Q: Are they suitable for automated TIG welding?

A: Absolutely. Smooth arc and consistent feedability make them ideal for both manual and automated processes.

Q: Do they retain strength under extreme heat?

A: Yes. They maintain toughness, ductility, and corrosion resistance at high temperatures.

Share