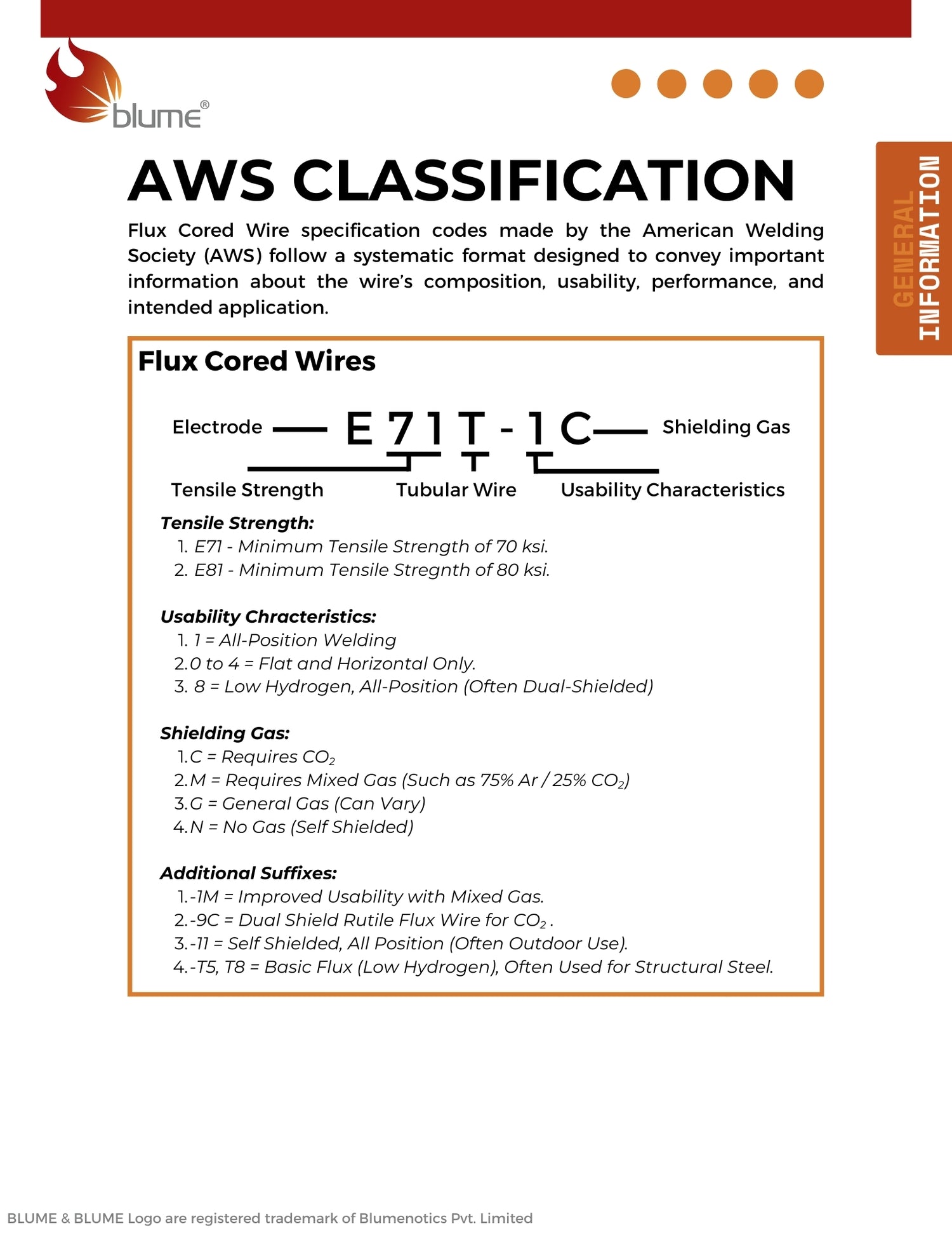

FLUX CORED WIRE

AWS CLASSIFICATION

Flux Cored Wire specification codes made by the American Welding Society (AWS) follow a systematic format designed to convey important information about the wire’s composition, usability, performance, and intended application.

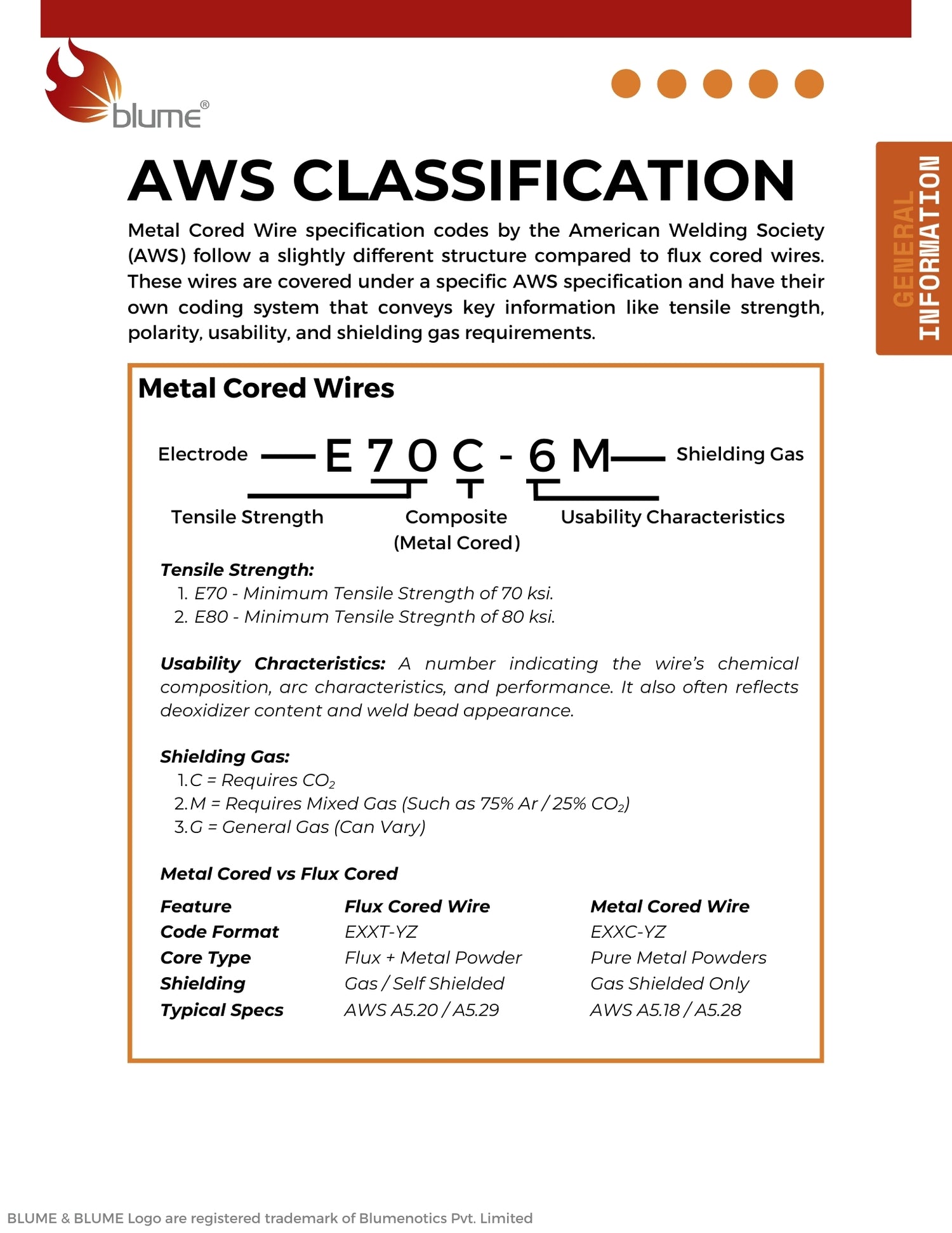

Metal Cored Wire

AWS CLASSIFICATION

Metal Cored Wire specification codes by the American Welding Society (AWS) follow a slightly different structure compared to flux cored wires. These wires are covered under a specific AWS specification and have their own coding system that conveys key information like tensile strength, polarity, usability, and shielding gas requirements.

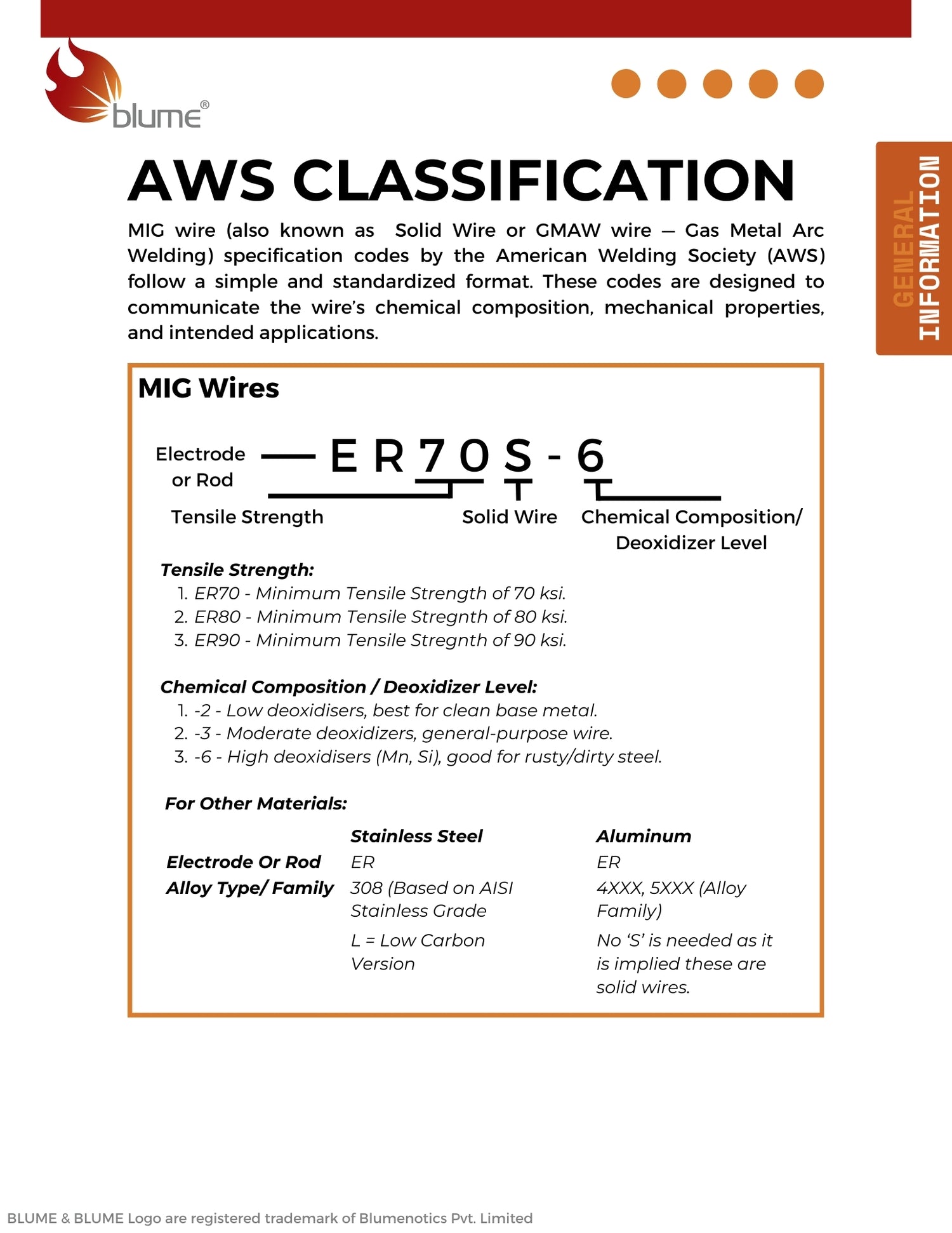

MIG Wire

AWS CLASSIFICATION

MIG wire (also known asSolid Wire or GMAW wire — Gas Metal Arc Welding) specification codes by the American Welding Society (AWS) follow a simple and standardized format. These codes are designed to communicate the wire’s chemical composition, mechanical properties, and intended applications.

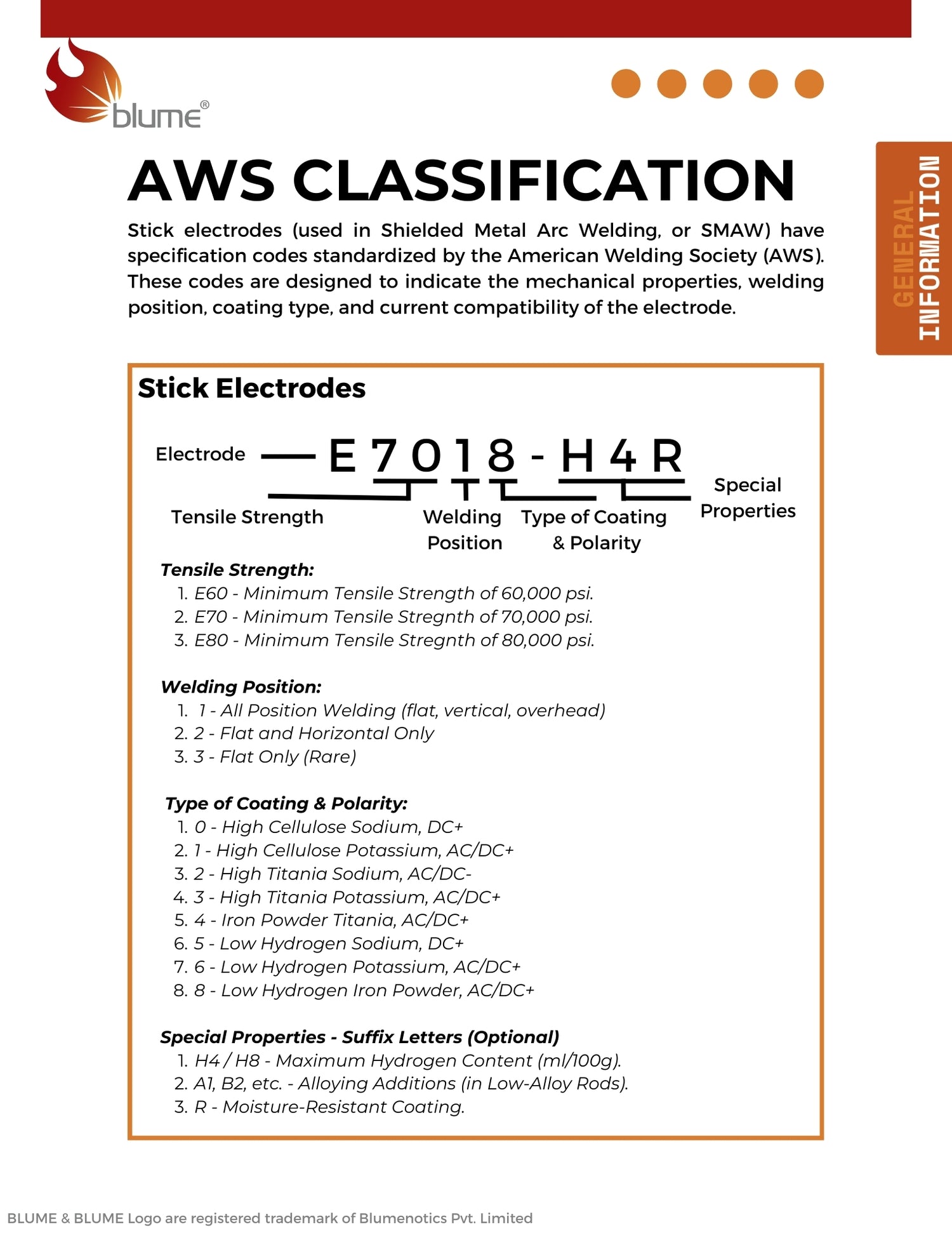

Stick Electrode

AWS CLASSIFICATION

Stick electrodes (used in Shielded Metal Arc Welding, or SMAW) have specification codes standardized by the American Welding Society (AWS). These codes are designed to indicate the mechanical properties, welding position, coating type, and current compatibility of the electrode.

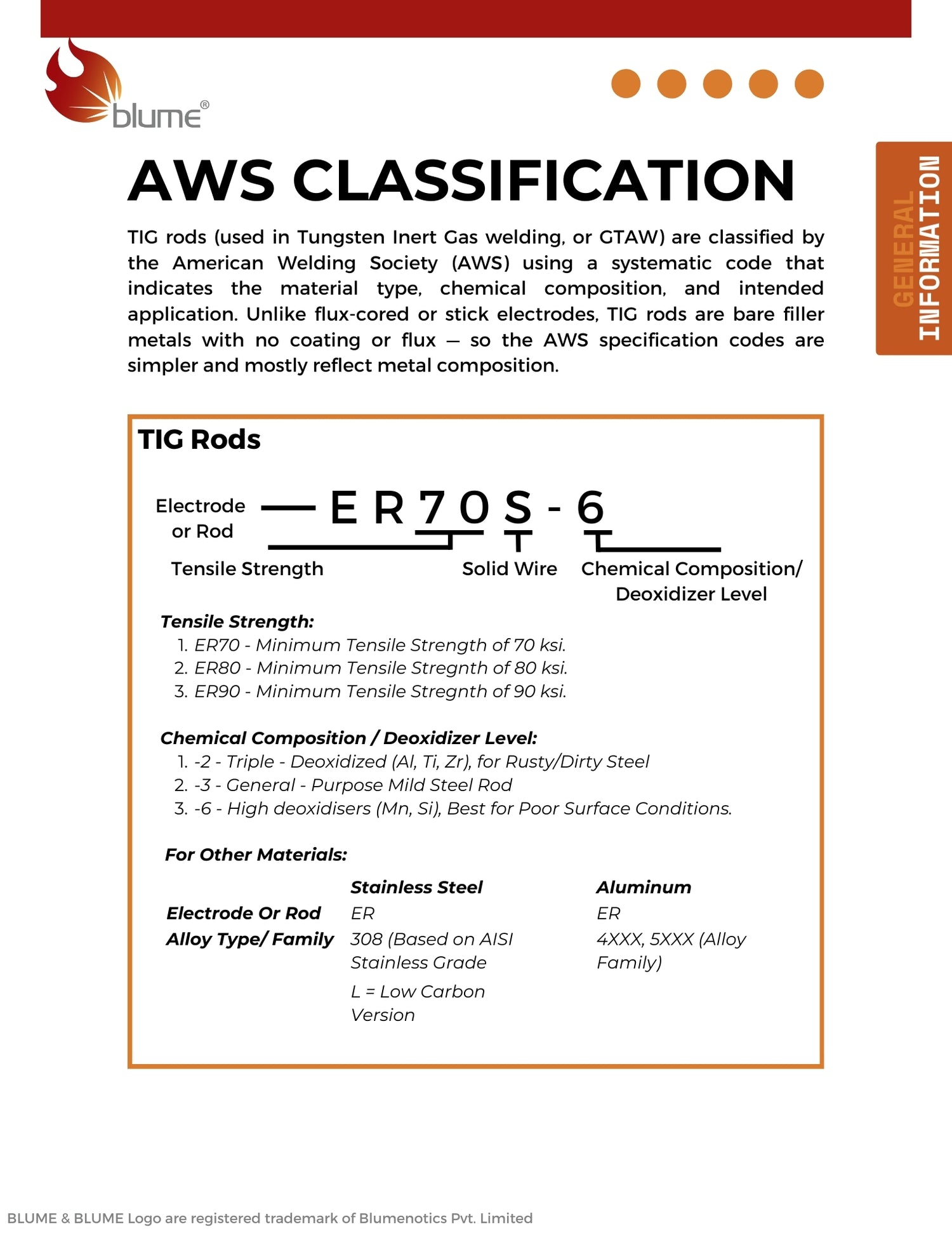

TIG ROD

AWS CLASSIFICATION

TIG rods (used in Tungsten Inert Gas welding, or GTAW) are classified by the American Welding Society (AWS) using a systematic code that indicates the material type, chemical composition, and intended application. .

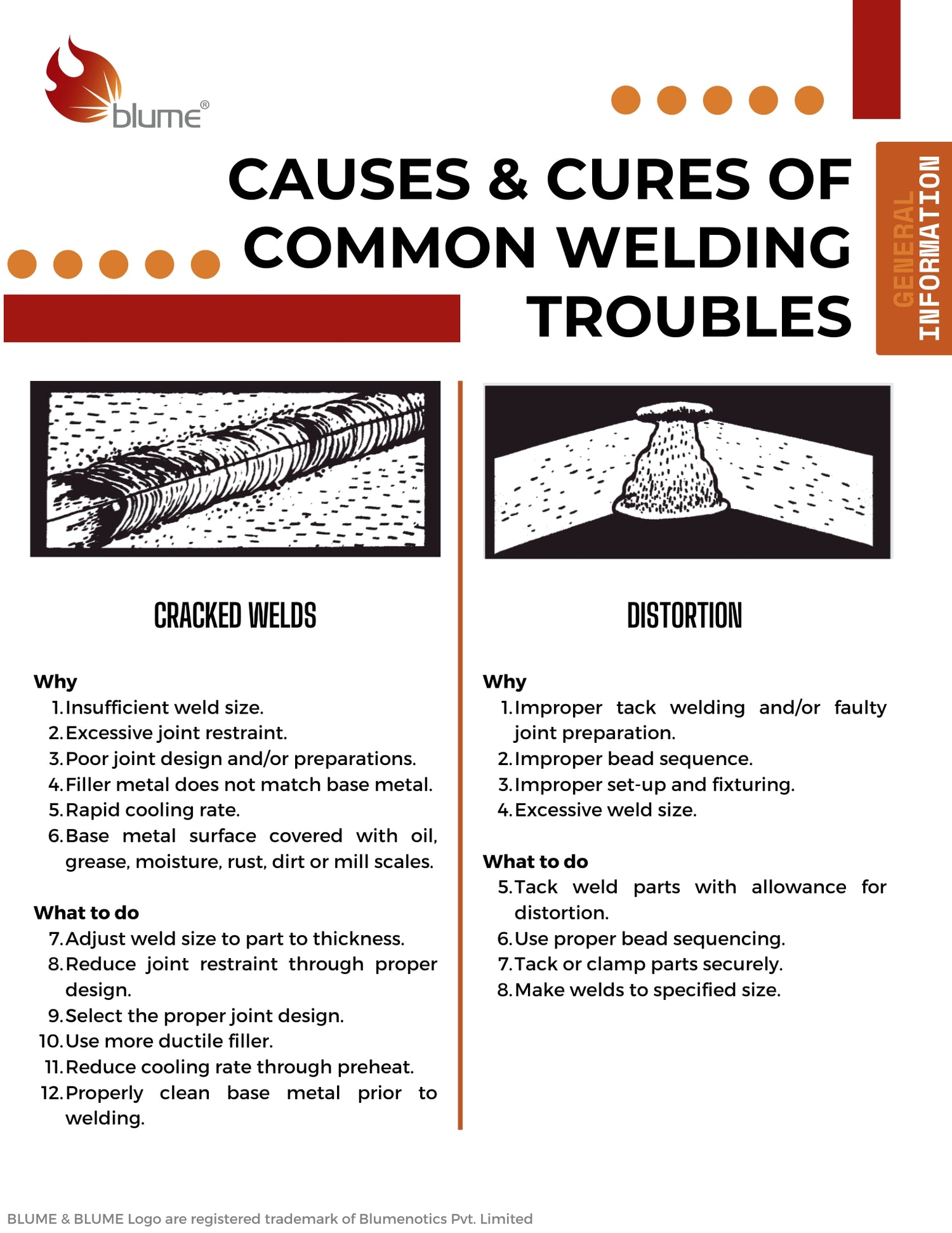

Causes and Cures of

COMMON WELDING TROUBLES

The Causes & Cures of Common Welding Troubles poster is a handy reference that highlights frequent welding issues and practical solutions to improve weld quality and efficiency.

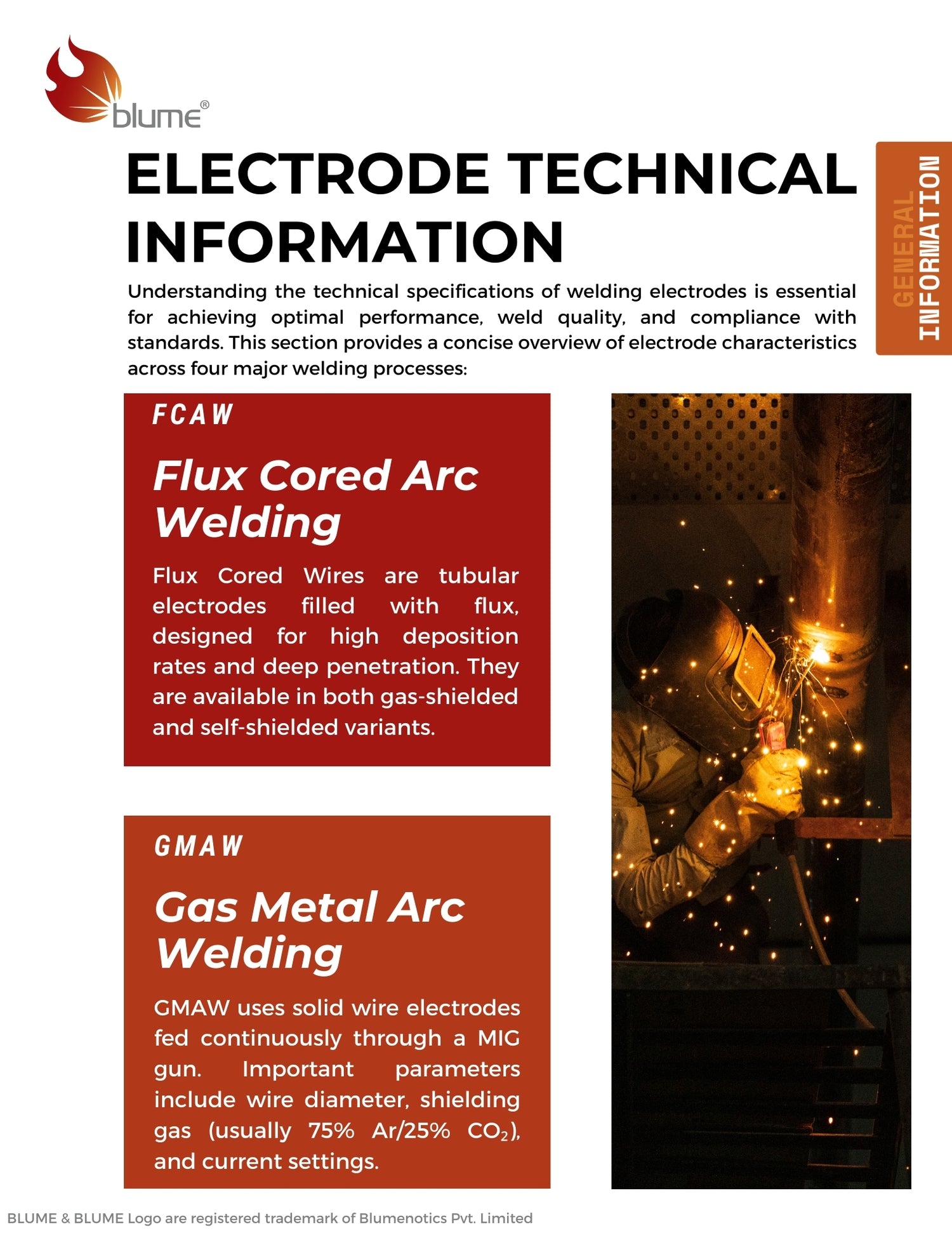

Electrode

TECHNICAL INFORMATION

Understanding the technical specifications of welding electrodes is essential for achieving optimal performance, weld quality, and compliance with standards.

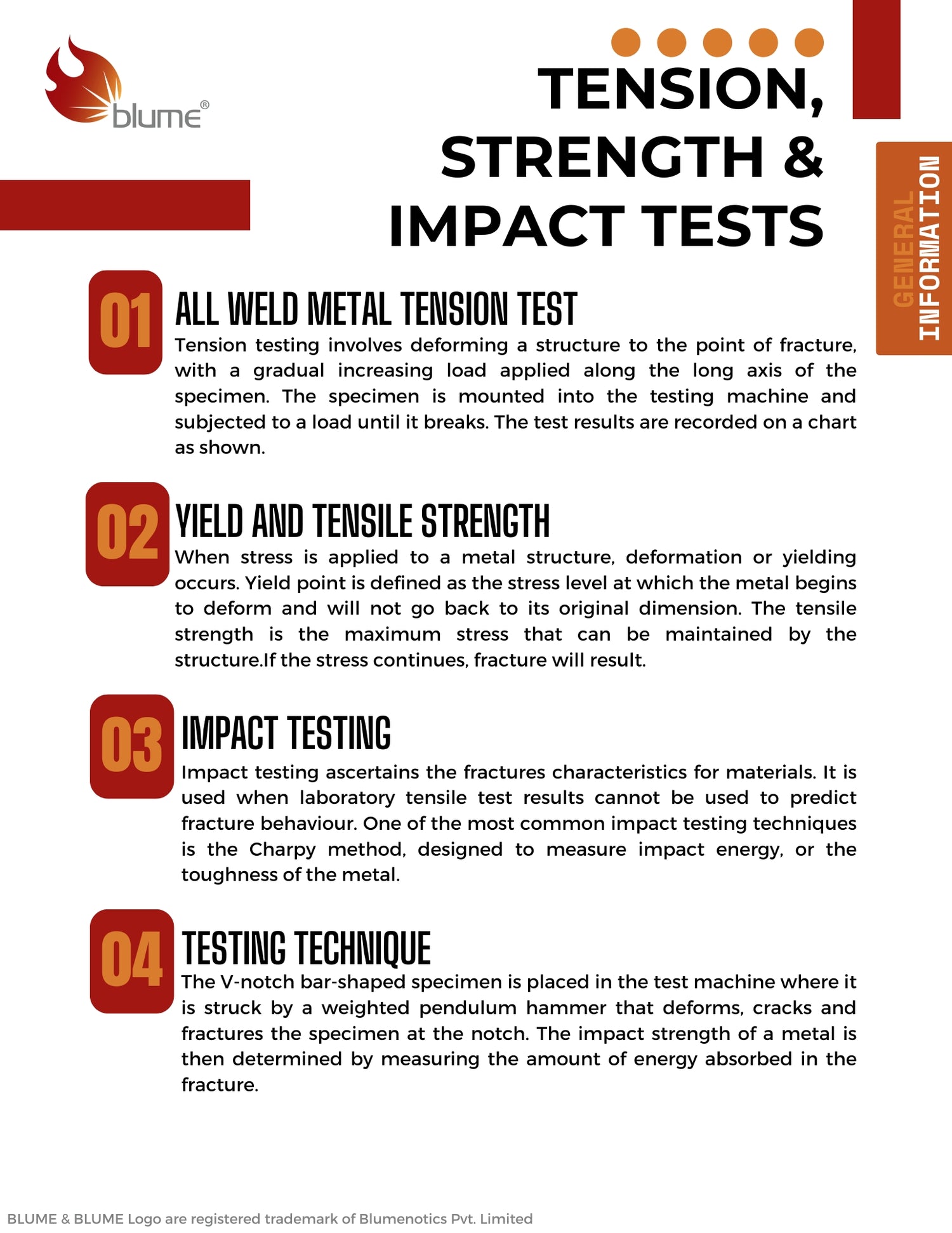

Tension, Strength &

IMPACT TESTS

The Tension, Strength & Impact Tests poster provides a quick reference to essential mechanical tests, helping welders and engineers understand material performance and quality.

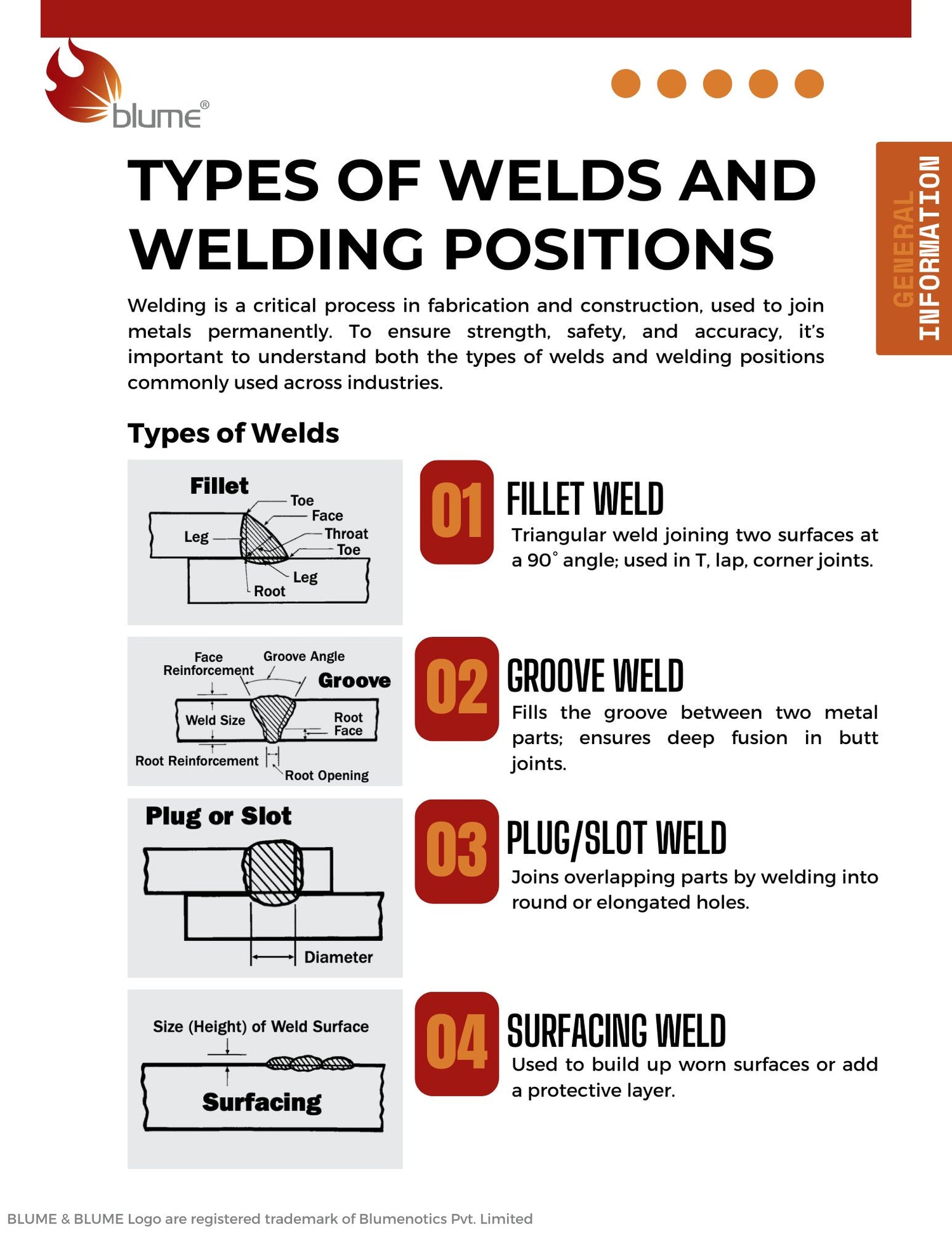

Types of Welds And

WELDING POSITIONS

Welding is a critical process in fabrication and construction, used to join metals permanently. To ensure strength, safety, and accuracy, it’s important to understand both the types of welds and welding positions commonly used across industries.